Plasma Cutting

Fast, Precise, & Repeatable

Ironside provides plasma cutting for any type of job. Fast cutting and repeatability enable us to lower cost of production without sacrificing quality workmanship. From structural steel base plates to timber connection plates, our facility is setup with a CNC plasma cutting table to accommodate any plasma cutting project.

A plasma cutter uses gas and electricity. The gas is forced through a constricted opening at high pressure, at which point it contacts an electric arc that is sent through the nozzle. This process causes a reaction, and the gas (typically nitrogen, argon, and oxygen) is heater to such a degree that it enters the forth state of matter, plasma. The plasma is so hot that it can melt through metal at a high enough speed that the excess material is blown away resulting in a relatively clean cut. Different gases are used depending on material type.

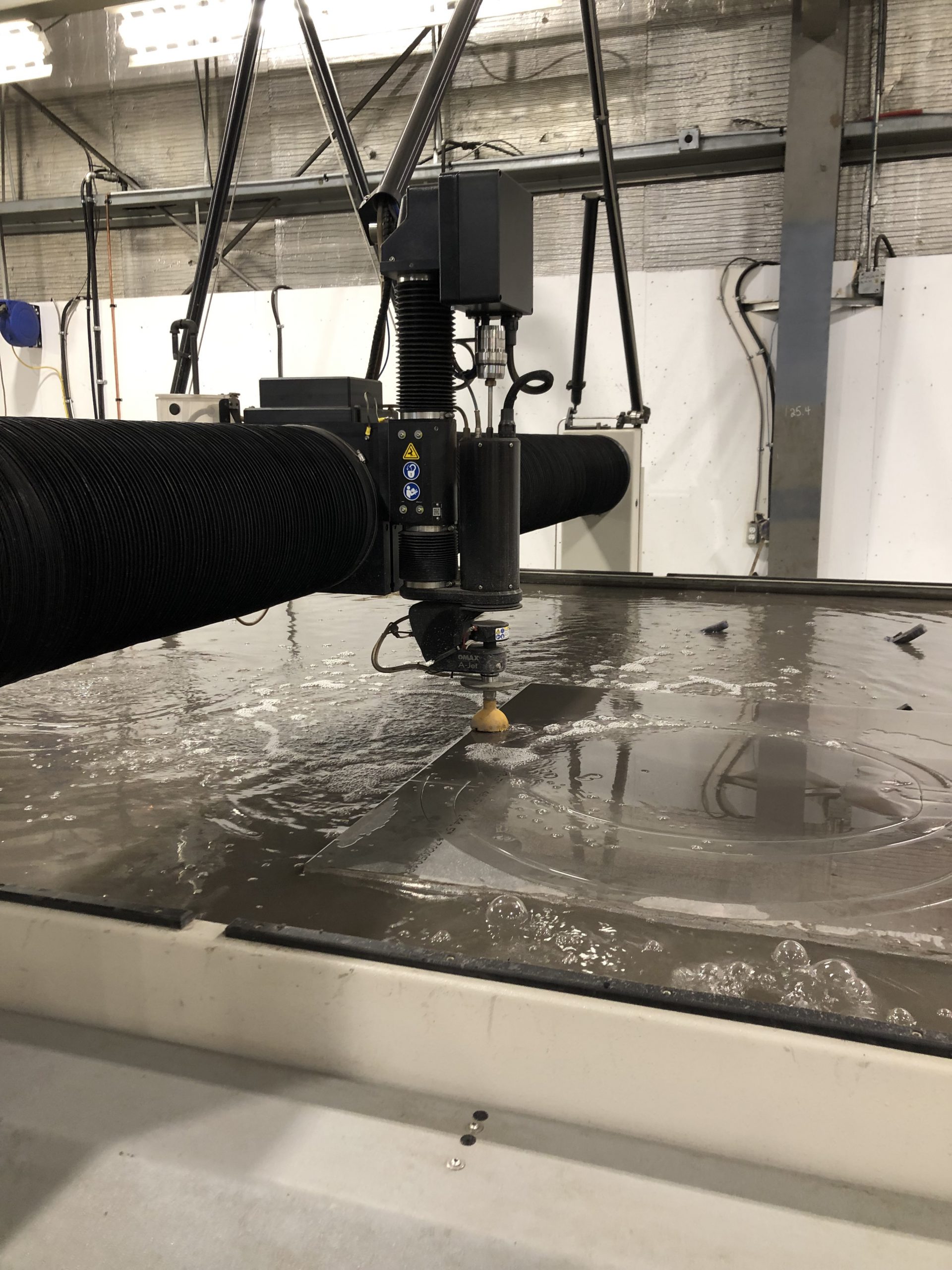

Waterjet Table

High Accuracy, High Quality, High Volume

The waterjet is a cutting system that relies on a mixture of water and abrasive to quickly break down material along a given path. Think of it as high speed-erosion. The abrasive (garnet) is fed through a line into a mixing tube where it meets 60,000 psi of water to form a fine cutting stream at the tip of the mixing tube. The nozzle then moves along the path determined by the CNC software at speeds that vary depending upon material type and thickness.

Quality

The plasma cutter can produce smooth cuts in many steels, with accuracy of +/- .01” – .03” depending on the setup. As material thickness increases, the cut will be less clean as the plasma struggles to melt through all of the material without producing unwanted slag.

The waterjet is considered the more accurate machine and will produce higher quality cuts across a wider range of materials and thicknesses, the waterjet can hold tolerances of +/- .001.

Cost

Both waterjet and plasma are affordable and effective methods for cutting material. On thinner steels, the plasma will be much faster and thus would cost less then the other alternatives.

The waterjet becomes more cost-effective on thicker plates, and materials that cannot be cut well on the plasma. The waterjet can also be more cost-effective in instances where secondary machining operations would otherwise be required.

Materials

The plasma is limited in what materials it can cut. For best results, it should be used primarily for steel, stainless steel, and aluminum. Non-conductive materials do not tend to cut well on the plasma. Thickness is also a factor in plasma’s cutting capabilities.

The waterjet is known for cutting nearly any material type. From hardened steels to softer materials like wood, plastic, and even food items like bread or cake, the waterjet will have great success across the board. Because the waterjet does not introduce heat into the material being cut, it is not limited by thickness and can cut thicknesses over 12” steel (though this would take a long time to cut).