Contract & Custom Manufacturing

Metal Manufacturing Projects Large And Small – All Under One Purchase Order.

Better Communication, Lower Transport Costs, Quicker Manufacturing

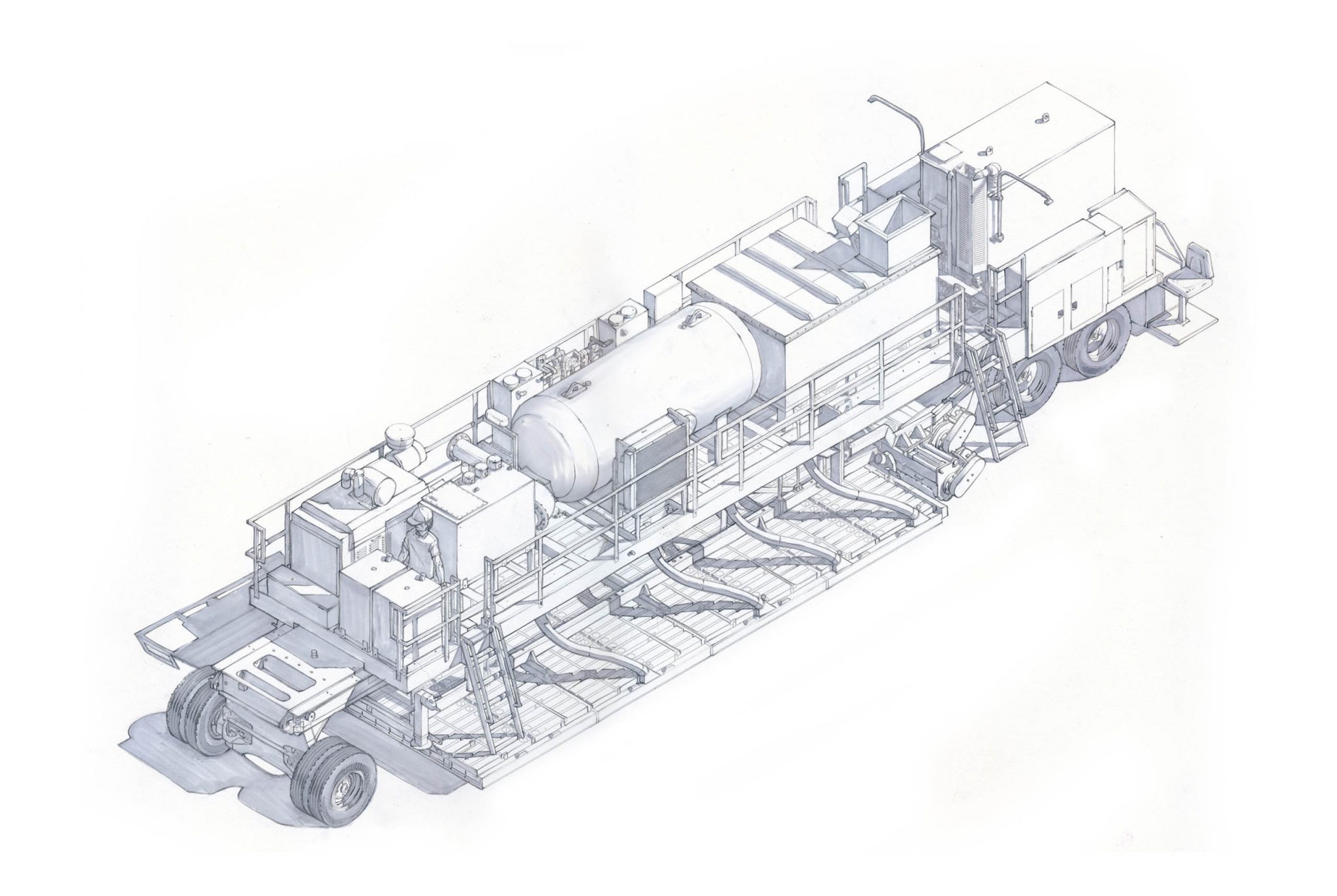

We Can Build Virtually Anything

If your mind can conceive it, we can build it.

Our in-house team of experts includes:

…plus a variety of other specialized groups. We have the capabilities and facility to take on custom design builds of a variety of sizes, all under one purchase order.

From conception to completion, we handle every aspect of a design-build project for our customers.

PHASE 1: CONCEPTION

Stop complications before they even happen.

The conception process is meant to help us preempt any complications that may arise from the design layout, during the build process, or even while out on the field during testing.

Feasibility Studies

This is the most important step in any custom design build project. It is at this point we ask:

Will It Work?

We have strict standards to meet with every custom design build. We consider, document and analyze everything from start to finish.

Every variable needs to be considered for the success of the project:

Steel will rust away in the ocean. Hot climates will cause an engine to overheat. Our feasibility studies stage will help ensure there are no oversights. If there’s a flaw found in the design, we’ll fix it and make sure everything complies.

Risk Assessment

Our top priority: safety

Every design must comply with the safety regulations of the country where the machine will be operating. We make sure the design is approved and adheres to environmental regulations.

PHASE 2:

DESIGN & BUILD

Together our engineers and draftsmen collaborate to build the custom design. From blueprint, the machine will start to take form. All fabrications are built in-house so we can ensure quality control.

Execution Planning

& Scheduling

Ironside’s facility is robust and resourceful

With a space of nearly 70,000 square feet, we can custom fabricate nearly any kind of custom project. The space is divided up into several specialized areas:

Planning and executing on multiple parts of a large-scale project is never a problem with our vast in-house team of long-standing professionals.

Our Team

Field Testing

During this shop and field testing stage, our highly specialized team will test the capabilities of the finished machine.

Everything from transportation, assembly (if necessary), and function will be scrutinized. Our technicians will observe the machine in the field, working with it just like you would. If issues arise, they can usually fix them on the spot, or our team will initiate a plan to assess and correct it.

We Welcome Smaller Projects

Smaller custom jobs get the same royal treatment as large custom jobs!

Small projects can still require all the steps as large design-build projects. We enjoy working with pre-built prototypes or already-finalized blueprint designs. Whether it’s a stand-alone small design or a specific piece of a larger machine, we can build it.

The Advantages Of A Single Purchase Order

Most manufacturing shops only offer services in one or two areas. They might have a CNC machine, but they don’t have electricians. They might be able to weld together your project, but they don’t have a hydraulics department.

We’ve had past clients who had to hire 3, maybe 4 different manufacturers to complete a job. This leads to a lot of wasted time, higher manufacturing costs, and overall it’s just more work for you.

If you’ve made it this far, you’ll realize that we can do everything in-house, meaning your project is done with a single purchase order.