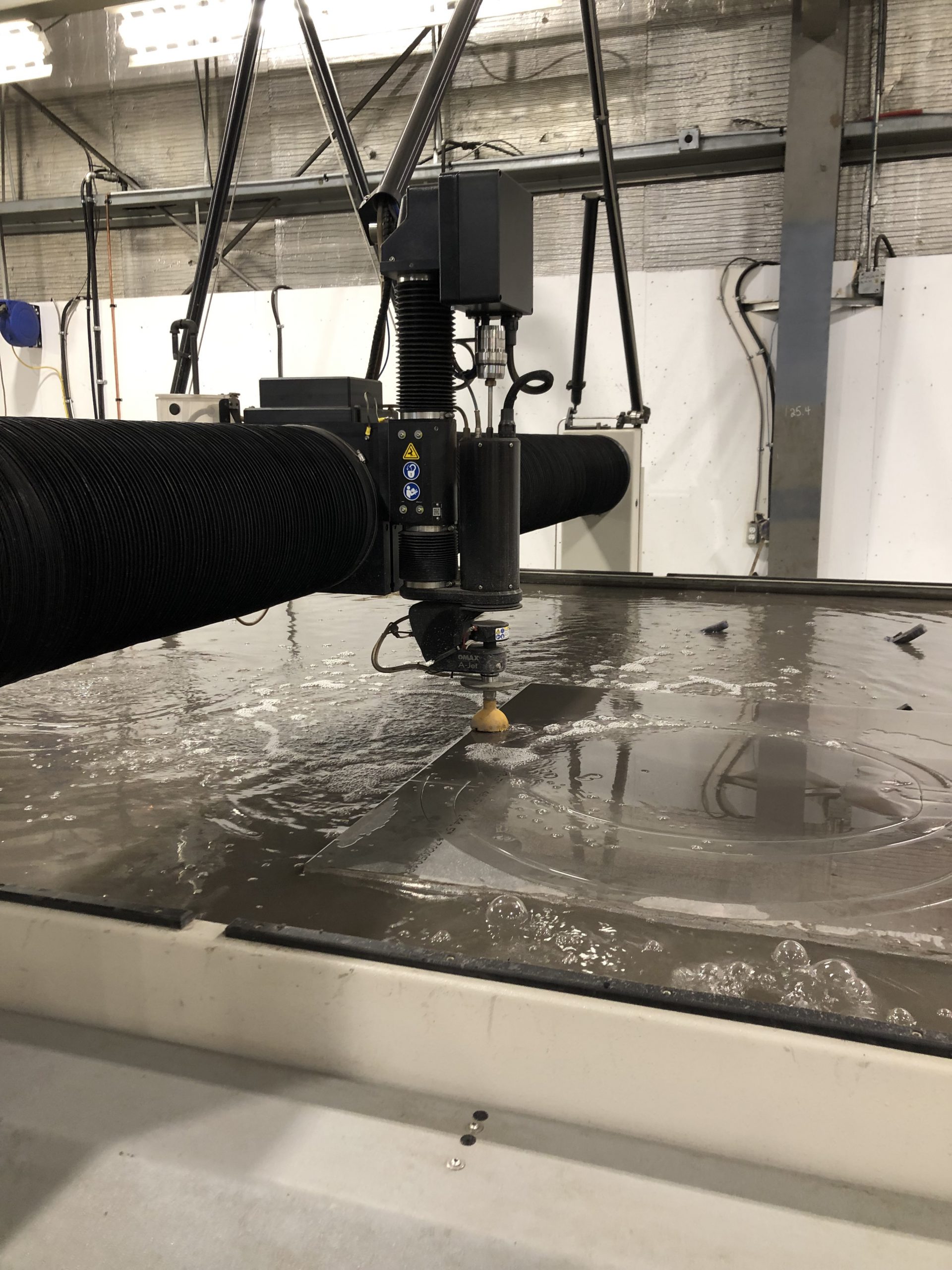

Waterjet Table

High Accuracy, High Quality, High Volume

The waterjet is a cutting system that relies on a mixture of water and abrasive to quickly break down material along a given path. Think of it as high speed-erosion. The abrasive (garnet) is fed through a line into a mixing tube where it meets 60,000 psi of water to form a fine cutting stream at the tip of the mixing tube.

The nozzle then moves along the path determined by the CNC software at speeds that vary depending upon material type and thickness.

Quality

The waterjet can produce a high quality cut across a wider range of materials and thicknesses,, while holding tolerances of +/- .001.

Cost

The waterjet table is an affordable and effective methods for cutting material, particularly cost-effective on thicker plates, and materials that cannot be cut well on other types of tables, like a plasma table. The waterjet can also be more cost-effective in instances where secondary machining operations would otherwise be required.

Materials

The waterjet is known for cutting nearly any material type. From hardened steels to softer materials like wood, plastic, and even food items like bread or cake, the waterjet will have great success across the board. Because the waterjet does not introduce heat into the material being cut, it is not limited by thickness and can cut thicknesses over 12” steel (though this would take a long time to cut).